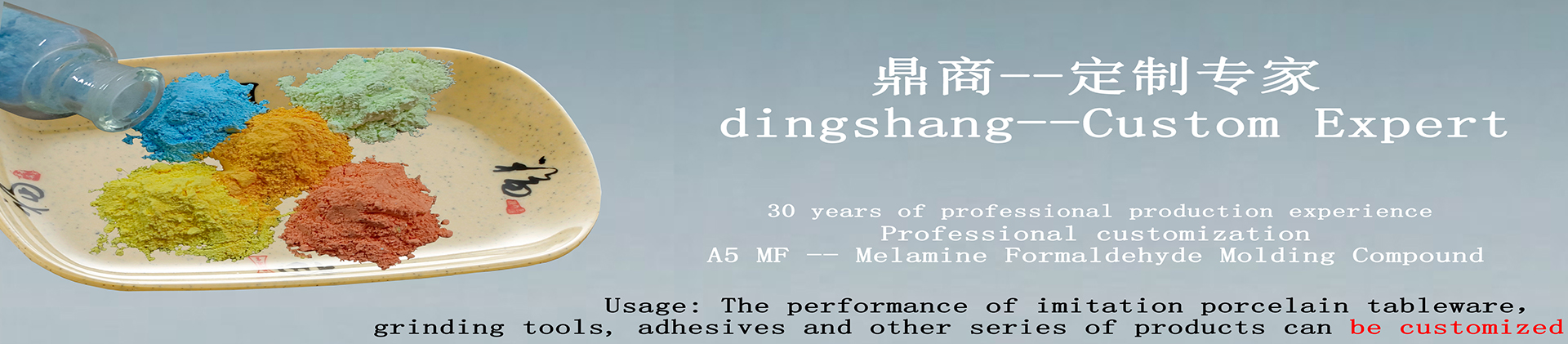

Melamine Glazing powder

所属分类: Melamine Glazing powder Series

产品简介:Melamine Glazing powder, also known as Glazing powderUsed for glazing and brightening tableware, printing flower paper on tableware,grinding tool adhesive

产品详情

CAS : 68002-20-0

Molecular formula : C4H8N6O

HS code : 3909200000

packing : 10kg/20kg/25kg

Sample : Free 1KG sample is provided, and no shipping fees are borne.

Product : Support customization.

Loading capacity : 18 foot container: 20-22 tons

20 foot container : 27.6 tons

Melamine Glazing powder

Also known as melamine coating resin,、Glazing Powder

1. The melamine dishes and porcelain like tableware made from the masking powder produced by high-pressure triamine method are flat and beautiful, with good density, low material consumption, high temperature resistance, large coverage capacity, fast molding time, high fluidity, good brightness and hand feel, good product quality and delicacy.

2. Used for making adhesives and decorative paper; Add various grinding tools such as dry grinding discs and water grinding discs to improve viscosity and hardness.

3. Surface coating of melamine tableware, imitation porcelain, and melamine tableware - After adding light powder, it solidifies with the resin base material to form a transparent protective layer, making the surface of the product smooth, resistant to weak acid and alkali corrosion, oil stains, and aging.

4. Using light powder can also paste various colorful printed papers on the surface of imitation porcelain products, thus obtaining products with rich patterns.

matters needing attention:

1. It should be stored in a sealed container, avoiding direct sunlight and preventing contact with moisture; After use, the inner packaging plastic bag should be immediately tied tightly, and the bag opening should be tied tightly to avoid moisture and deterioration.

2. Packaging: Generally packaged in 10kg paper plastic composite bags. Lined with 1-2 layers of plastic film bags.

3. Storage: It should be stored in a ventilated, dry, and cool indoor environment (<30 ℃). Storage period: 6 months from the date of manufacture. If the period is exceeded, performance evaluation should be conducted, and qualified products can still be used. After technical improvements in our factory, it must be extended to 12 months under the same conditions.

4. Transportation: Avoid moisture, heat, contamination, and packaging damage.