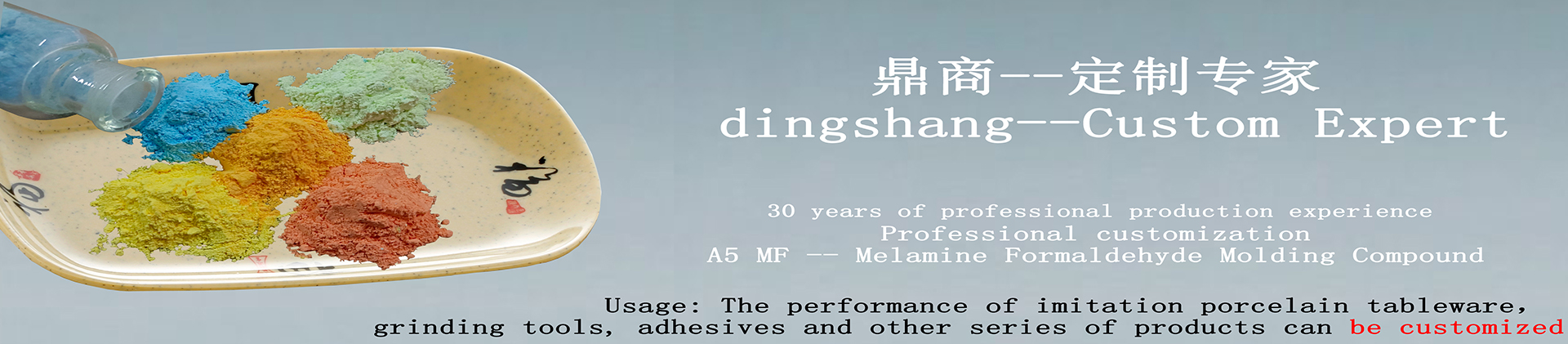

Dingshang Chemical - a leading global provider and manufacturer of solutions for amino molding materials

**Enterprise Inheritance**

Located in Shijiazhuang, Hebei Province, as a strategic emerging enterprise, Dingshang Chemical (established in June 2022) integrates 30 years of experience in the research and production of amino molding materials from its parent company (established in 1994), focusing on providing global customers with A5 amino molding material full industry chain solutions. Relying on the industry-leading production capacity of 28000 tons/year at our headquarters, we continue to maintain our position as one of the top three exporters of amino molding resin powder in China.

**Core advantages**

✓ * * Technology Leader * *: The first batch of A5 material production enterprises in China to introduce intelligent production equipment through technological innovation and reform

✓ * * Customized Innovation * *: We have established cooperation with the New Materials Research and Development Center of the University of Science and Technology to support the development of functional modification (high temperature resistance/high gloss/food grade, etc.) products

✓ * * Intelligent Manufacturing Benchmark * *: Two major intelligent production bases in Shijiazhuang, with a key process automation rate of 92%

✓ * * Quality Commitment * *: Raw material+production+testing full traceability system, product batch qualification rate has exceeded 99.6% for 8 consecutive years

**Product Matrix**

▶ Substrate series: Melamine powder (industrial grade MF-2615/2617/1191, etc.)

▶ Enhanced material: High flow coating powder (DZ-240/LG110/LG220/LG250)

▶ Special resin: melamine formaldehyde resin (environmentally friendly/flame-retardant)

Application areas: covering 18 industries including high-end melamine tableware, insulation components, grinding tools and abrasives, adhesives, etc

**Intelligent manufacturing strength**

Shijiazhuang Equipment Manufacturing Base

-Ball milling system : 50 intelligent grinding units with a daily production capacity of 50-60 tons

-Fully automatic production line: 2 German technology base material production lines (60 tons/day)+1 coating powder dedicated line (20 tons/day)

-Resin synthesis center: 2 sets of DCS controlled reactor systems (15 tons/day)

Luancheng Youtong Village Base

-Supporting 15 new grinding equipment, focusing on large-scale production of melamine powder (20 tons/day)

**Value commitment**

With 30 years of vertical cultivation experience and a 98% customer repurchase rate, we offer:

√ Flexible production: supports personalized orders with a minimum order of 1 ton

√ Technical escort: The engineering team follows up on product application throughout the process

√ Professional customization: Our company specializes in the customized production of Melamine Moulding Compound ,Melamine Glazing powder, and melamine formaldehyde resin. We can develop different models and performance specifications of products according to customer needs, and provide strict quality control services.

We sincerely invite global partners to conduct on-site inspections of intelligent production line workshops and create a new ecosystem for the application of special materials!